Learn to make cold process soap at home, using only kitchenware, vegetable oils, lye and water. Kitchen ingredients work as natural colorants and essential oils will give your soap natural lovely scents. In cold process, soap is made at temperatures near room temperature (40ºC-25ºC). The resulting soap has a surprisingly professional look, while still looking handmade.

Find below a detailed step-by-step tutorial that will show you how to make cold process soap, a method that does not require heating, just what is necessary to melt solid oils and butters. Cold process is the easiest and mostly used method to make handmade soap from scratch. In the end, you will get 100% natural soaps, beautiful, very moisturizing and soft and with a professional look.

But first let’s learn a couple of notions necessary to fully understand the cold process method. In addition, if you subscribe to the newsletter, you will receive a free e-book where you can learn soap making basic chemistry.

Table of Contents

- What Is Cold Process Soap?

- What Is Trace in Cold Process Soap?

- What Is Gel Phase in Cold Process Soap?

- What Is Superfat?

- What Is Soda Ash?

- Safety First!

- Make Cold Process Soap Tutorial

- Step 1: Prepare your Workstation – Gather Ingredients and Equipment

- Step 2: Measure all Ingredients

- Oils, Lye, Water

- Essential Oils and After Trace Ingredients

- Natural Colorants

- Step 3: Heat the Oils

- Step 4: Prepare the Lye Water

- Make Lye Water

- Step 5: Temperatures to Mix Lye Water With Oils

- Step 6: Reaching Trace

- Step 7: Add After Trace Ingredients

- Add an Antioxidant

- Step 8: Molding Your Soap

- Molding Soap

- Step 9: Clean up your equipment

- Step 10: Unmold and Cut the Soap

- Step 11: Curing and Storing Soap

- Related Posts

What Is Cold Process Soap?

Handmade soap is produced by mixing oils with lye water through a chemical reaction called saponification. Yes, it’s that simple:

OILS + LYE (CAUSTIC SODA) + WATER -> SOAP SALTS + GLYCERINE = SOAP

The cold process method is the most common way to make soap from scratch, with these three ingredients. Cold process, as the name implies, refers to the temperatures used in mixing the ingredients. It is simpler than the hot process method, which involves a heating source and a slightly different step sequence – basically, an “accelerated” saponification.

It is easy enough for anyone to try and you can easily make soap in the kitchen using this process. No need for very weird ingredients or heavy industrial machinery. There is usually some uncertainty in the first attempt. But in the second you’ll get the hang of it. In the third, you will love it and start feeling “addicted” – welcome to soap makers’ world!!!

What Is Trace in Cold Process Soap?

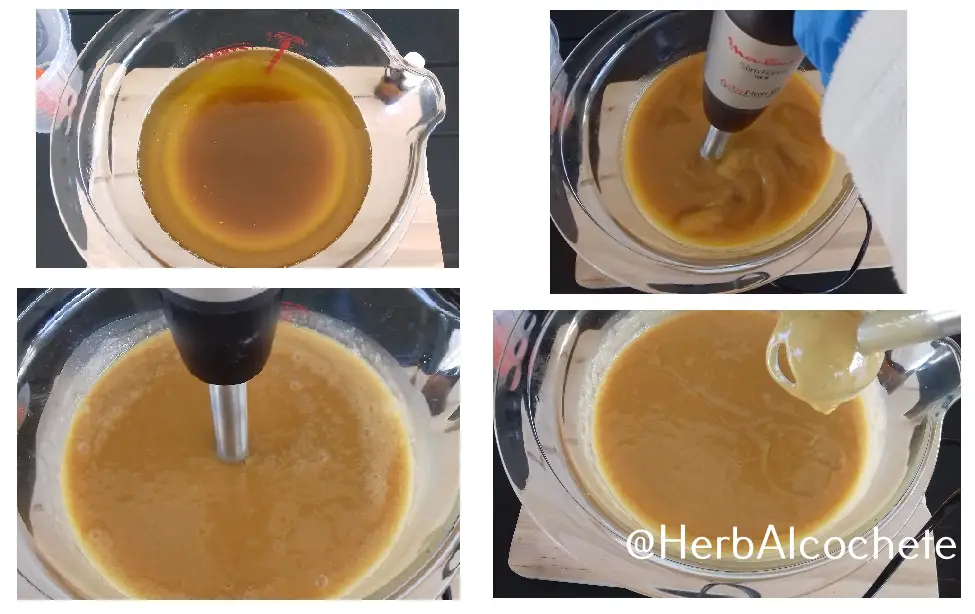

It is when you no longer have oils and lye water, but an homogenous mix of both. The soap batter looks similar to liquid pudding, or a thick fluid that can leave marks when you mix it.

Best way to know you have reached trace, especially when you are just starting, is to find the visual characteristic marks in the soap batter when you lift your immersion blender – the ones that give “trace” the name. The marks will remain in the soap surface unless you mix it again, pretty much like liquid pudding.

This is actually better understood when you *see* it, rather than learn it by words:

What Is Gel Phase in Cold Process Soap?

Gel phase happens during the heating stage of saponification. After your soap is in the mold for a bit, when it’s setting, you will feel that it starts to heat up – saponification is an exothermical reaction. If during this stage, the soap reaches a certain temperature, it changes from opaque to translucid, and its color darkens, gets more intense.

You will definitely see it when you use large mold boxes, at the center, as a darker circle. It’s more difficult to see it in individual molds as the soap cools down faster, and most of the times doesn’t go through gel phase. See below two soaps with same colorant, one that hasn’t gone though gel phase and the other that did. See the differences?

Many soap makers “force” gel phase, as a way to make colors more intense, by thermally insulating the soap mold. In my recipes, when using a large soap mold, I always instruct to insulate it, so that your soap is even, with no darker circle in the middle. See this article to learn more about gel phase.

What Is Superfat?

Oils react with lye water creating soap. Superfat is when some part of those oils remain oils, while all the lye water is transformed into soap. They are also called “unsaponified oils” because they don’t suffer saponification.

Superfatting your soap have two goals:

- Soap safety! Supperfatting is your safeguard that ALL lye will be consumed and transformed into soap, and you won’t be rubbing any lye in your skin.

- Conditioning, moiturizing properties: with a small percentage of floating oils in your soap, added to natural glycerin, your soap will very mildly hydrate your skin while you wash yourself. See this more like a means to not dry skin than to actually moisturize it. But it works!

Superfat can be 5%-20%. Most of the times is 5%. 100% coconut oil soap recipe uses 20% as a special case.

What Is Soda Ash?

Soda ash is sodium carbonate. It is a white powder, looking like “white ash”, that forms on the surface of soap: when lye (sodium hydroxide) reacts with the carbon dioxide in the air.

This powder is completely harmless, but may be a nuissance for your pretty colors and designs. Or not! You might just like it, and be willing to have it on your soaps. It happens especially when your soap recipe has a lot of liquid oils. You can prevent it, by sprinkling your soap with alcohol (it prevents contact with air).

Safety First!

Before starting ANY soap making recipe, it is important that you equip yourself with safety equipment: goggles, gloves and a mask. Also, be fully clothed, including your feet: no sandals.

Make sure you wanr all people that you will be dealing with a corrosive chemical (sodium hydroxide). Prevent to have children or pets around. Check out the post with all Safety Precautions in Soap Making or watch the video below:

Make Cold Process Soap Tutorial

These step-by-step instructions for making handmade soap presented are generic and, apart from some details, serve to follow any type of cold process soap making recipe. There will be no list of ingredients or quantities and we’ll speak generically of the various steps. Check out the Recipes category for actual soap recipes.

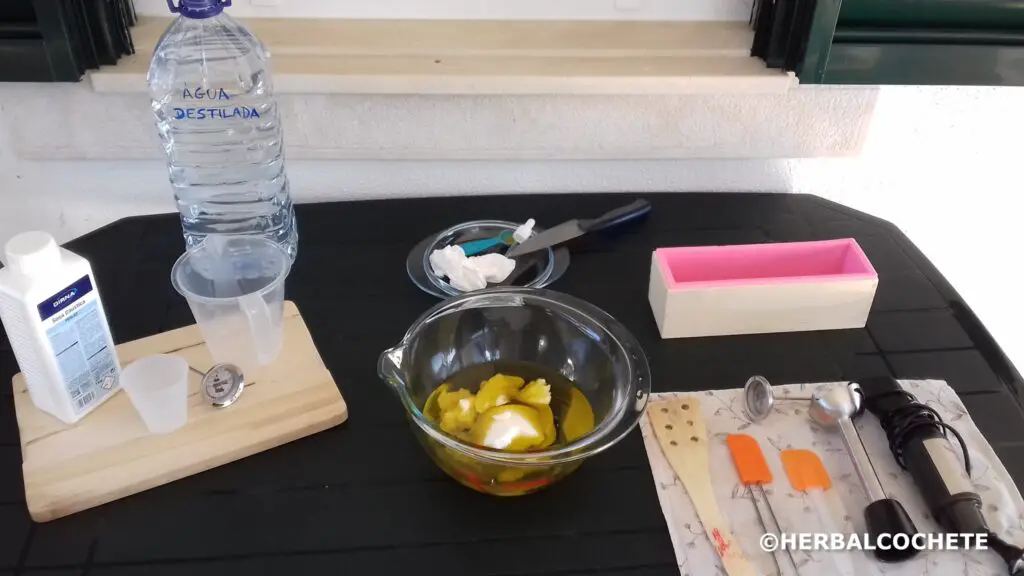

Step 1: Prepare your Workstation – Gather Ingredients and Equipment

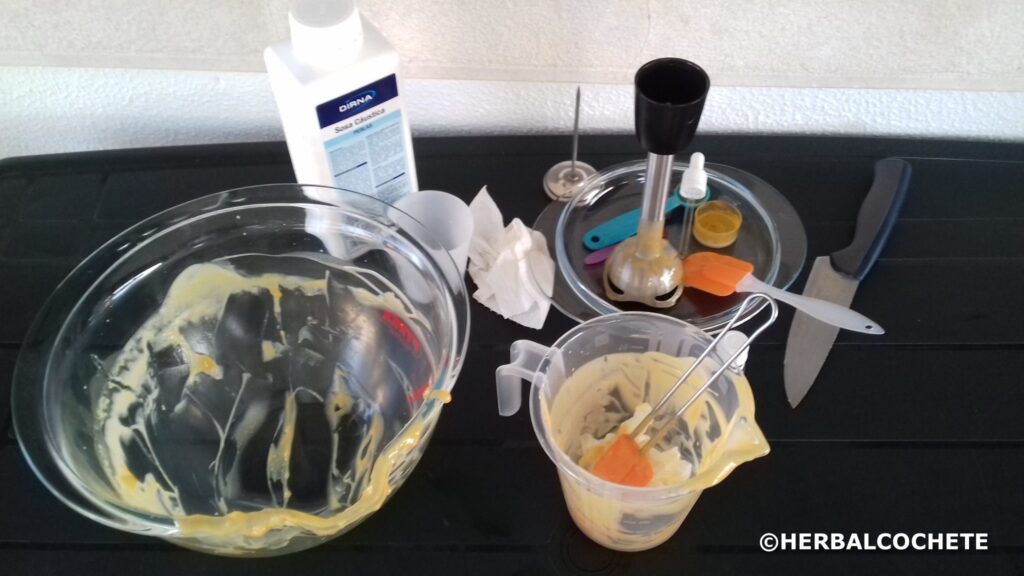

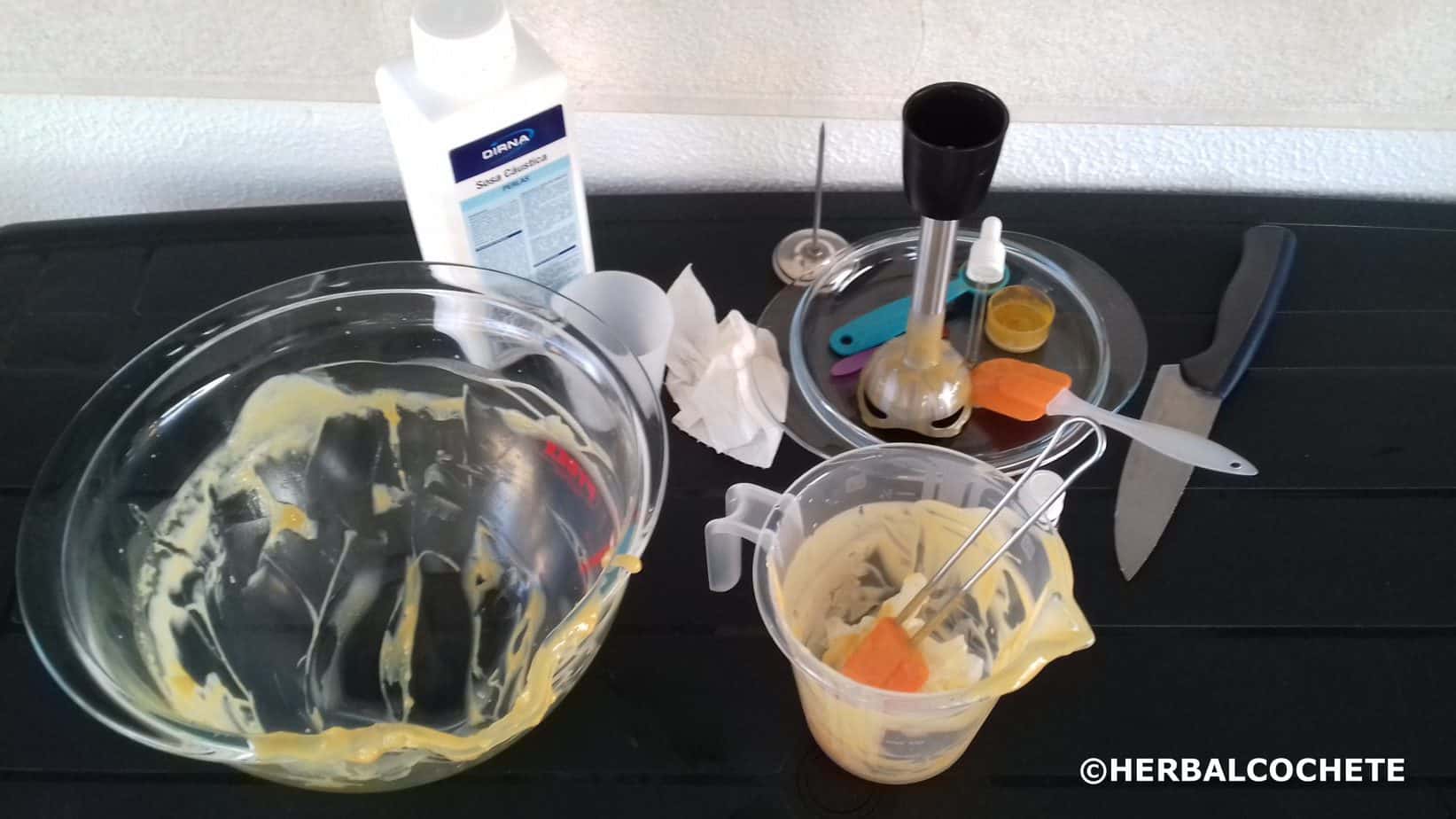

It is important to have everything prepared and organized before you start preparing the soap batter. This includes gathering ingredients, preparing your workstations and organizing equipment.

I don’t advise in the middle of the recipe to pick up any missing ingredients or necessary equipment. You should be totally focused in the soap batter, and have everything within hand’s reach until you have yous soap in the mold.

It is also not good practice to measure ingredients in a hurry, it leads to measurement errors and can compromise the quality of the final soap, for example, adding too much lye can make the soap irritating to the skin! (remember talking about superfat?)

Take the time to read and understand all the steps in this tutorial, as well as each recipe. Then, prepare everything you will need for the recipe. Never failing this important preparation step is halfway to a smooth soap making experience. You will also have less work in cleaning up, believe me!

To know what sort of equipment you might need, check out Where To Buy Soap Making Equipment.

DO NOT use ANYTHING in metal to make soap, especially aluminium. Lye corrodes metal. The only exception is stainless steel. Better go for silicone and pyrex.

Step 2: Measure all Ingredients

In order to be more efficient, or just make less mistakes during soap making, I start to measure ALL ingredients:

Oils, Lye, Water

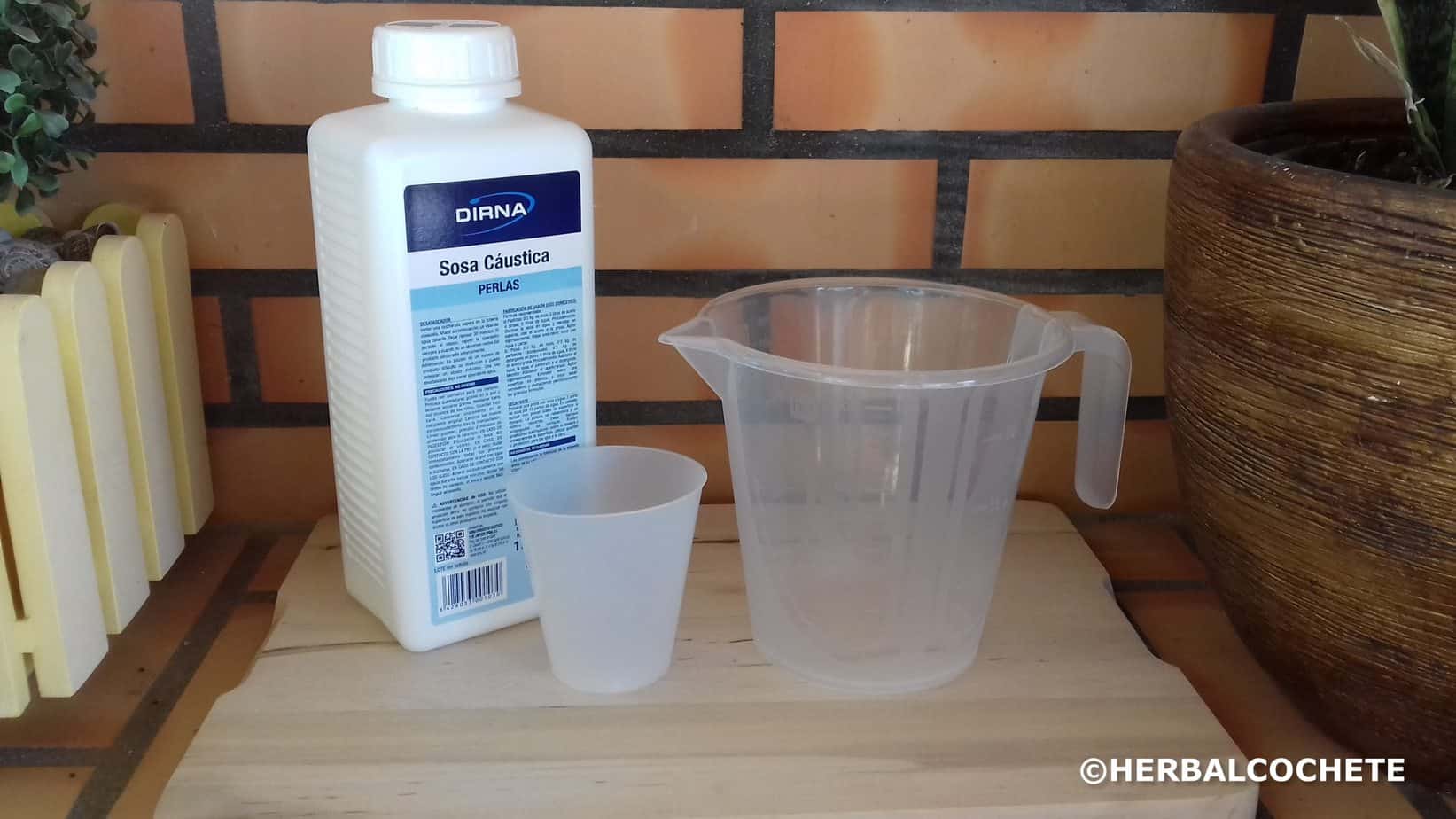

1 – I weigh carefully the quantities of oils and butters, water and caustic soda with a scale. Oils go to a microwave-safe bowl (pyrex) where I will be making the soap batter. Water goes to a pitcher (heat resistant) where I will be making the lye water. Lye goes to a cup.

Everything is measured with a digital scale. They usually have an acurracy of 1 gram. You should stick to making errors no bigger than 1 or 2 grams. Don’t add or remove like 20g of lye, water or any of the oils, you are changing a carefully calculated recipe. Your final soap might get irritant, too soft, no lather, etc.

Don’t forget to reset the scale for each ingredient.

Essential Oils and After Trace Ingredients

2 – I then measure the essencial oils with measuring spoons or a pipette with scale (ml). You can also use a digital scale (in mg), but essential oils weight is not so critical. You just need to be careful NOT to exceed the maximum % for soap making: 3% of weight of oils.

I usually make a very rough approximation from mg of the recipe to ml, which usually results in less essential oils weight than the soap calculators call for, which is safe. Check out more about essential oils measurements and safety in Are Essential Oils Safe For Soap?

In this step, I usually add the antioxidant extract, or any other ingredients I might need to add after trace. Everything goes to a small bottle or cup, then I just need to pour it in the soap after trace in one go.

Natural Colorants

3 – At last, I measure the amounts of natural colorant, again, with measuring spoons (in ml). In these photos, I used turmeric and red iron oxide as dyes ? I put the mixture in a small cup.

After these preparations, we will have to organize everything in workstations or work areas that must include the following utensils:

- Heating Area: to melt / heat the oils. equipped with 1 thermometer. It can be a microwave or a double boiler for bagne-marie.

- Soap Making Area: to prepare the soap batter, where the bowl with measured oils is already found, the bottle with essential oils and anti-oxidant and the cup with colorants. It must be equipped with: spoons, a spatula, a strainer (optional), 1 measuring jug, a plate where to put dirty items, some squares of kitchen paper and the immersion blender already plugged and prepared. You can prepare this area next to the heating area.

- Lye Water Area: an area to mix the water with lye. It is important that this area is well ventilated, ideally outdoors, or under a window. This area should have: a stainless steel spoon or silicone spatula, a thermometer, a large container with cold water to cool the sodium hydroxide solution (caustic soda).

- an area with the molds, and the prepared thermal insulation material (towels, blankets, or wooden boxes). Usually, it is next or in the soap preparation area.

Step 3: Heat the Oils

Is everything ready? So let’s start making soap!

The trick here is to heat the oils near 50ºC – 122ºF (even 45ºC – 113ºF) without any over heat. Overheating the oils may destroy some of their properties or essential nutrients.

I put everything in a microwave-safe pyrex large bowl and heat the oils until small pieces of the solid oils are left and let the rest melt out, mixing. Your microwave is probably different than mine, so it’s difficult to setup power and time. Start with a low power, or medium power and short periods of time, until you are able to learn the right settings to heat the oils – without overheating them.

If you’re using another process, I recommend bagne-marie and would avoid a stove with direct heat.

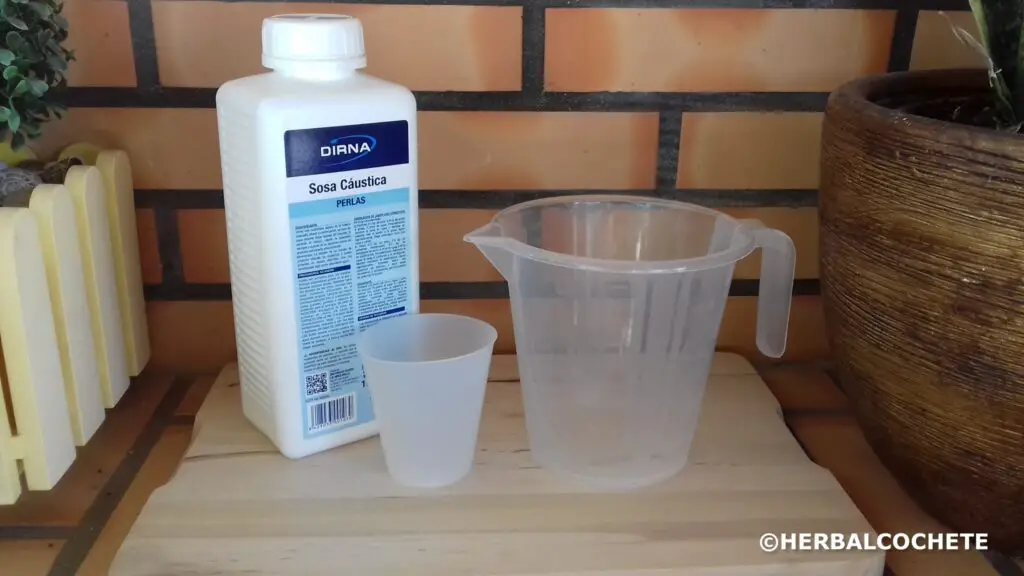

Step 4: Prepare the Lye Water

After the oils have heated in the microwave, let’s prepare the lye water, or the sodium hydroxide solution.

If you haven’t done so already, put now your safety equipment: gloves, glasses and mask. You must have clothes that cover your legs and arms, and shoes that cover your feet. Make sure that there are no children or animals in this area, to minimize the risk of accidents.

Using lye can (and should) be intimidating, however it is an essential ingredient in soap making. All soaps, even glycerin bases, are made with sodium hydroxide (lye).

Now, be prepared to place your lye water pitcher (ideally in pyrex or heat resistant plastic) in a container with cold water or on a heat-resistant counter. As soon as you mix the lye with water, it will reach temperatures in the order of 90º – 194ºF!

Do not use the refrigerator to cool the mixture, because the resulting vapors are corrosive and toxic, and may contaminate your food.

Make Lye Water

Slowly pour the lye into the container with the water and mix well with a silicone spatula or spoon. NEVER POUR WATER OVER THE LYE – you will have a volcano effect. Also, your water should be at room temperature, warm or hot water will also trigger a volcano effect.

The solution will heat up and release harmful vapors. Be careful and avoid breathing vapors. Mix very well so that the lye completely dissolves in the water.

You can make lye water with other liquids besides distilled water: water infusions, milk, fruit juices, etc. You may also add other ingredients at this stage: natural colorants, it will make the color more vivid; fine salt or sodium lactate to harden the soap and make it last longer; citric acid to prevent rancidity.

Check out Soap Making Lye Water to learn more.

Step 5: Temperatures to Mix Lye Water With Oils

What raises more doubts when making soaps is at what temperature to mix the oils with the lye water. Do they both have to be at the same temperature or not? What temperature?

In summary, most recipes call for a temperature of 40ºC – 104ºF to mix lye water with oils. It’s a temperature that balances many factors. It’s important that lye water and oils’ temperatures don’t differ more than 10ºC: don’t make the mixture if your lye water is at 60ºC and oils at 40ºC. Also, make sure that all oils are completely liquid: they should be a transparent liquid, and not cloudy.

Avoid high temperatures, above 55ºC, especially at the beggining. You run the risk of having a wide range of problems with the soap: volcano effect, cracks and discoloration.

If you miss the temperature to mix lye water with oils, you can do it at room temperature, with no issues. Just make sure your lye water and oils’ temperatures are close enough. You may also reheat the oils, but DO NOT heat the lye water.

With more experience, you can start “forcing” gel phase for brighter colors (see chapter before in this post), or use sugars in your recipe, therefore, working with higher temperatures. If you follow the recipes, there should be no issues.

Step 6: Reaching Trace

Now the interesting part will begin! Pour the lye water into the oil mixture.

Now, insert the immersion blender into the mixture and tilt it to release air bubbles. Turn on the blender for very short periods of time and then mix it up a little, using it as a spoon. The mixture will slowly stop being “oily” and start to take on a more milky, creamy and opaque consistency, especially when you switch on the blender.

Repeat these steps with the blender until you reach “trace”, avoiding air bubbles as much as possible. Depending on the amount of fat and the type of oils used it can take from 30 seconds to 15 minutes.

The type of “trace” turns out to be a preference of the soap maker: with a light “trace” (liquid mass) you can pour the soap batter into molds, almost completely avoiding the appearance of air bubbles; heavy “trace” (paste-like dough) allows to make reliefs, layers and textures, something impossible with the liquid mass.

Note: If you do not use an immersion blender, and choose a hand whisk or spoon, prepare to beat the soap dough for 3 hours until you reach trace…. Hence it is essential to use the immersion blender ?

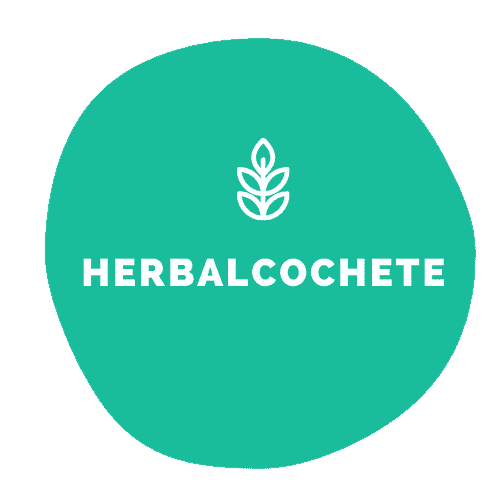

Step 7: Add After Trace Ingredients

After the soap has reached trace, it’s time to add after trace ingredients. These are “delicate” or temperature-sensitive ingredients whose properties may be destroyed with saponification or simply evaporate with high temperature, or, for some reason, are simply added at the end. These include essential oils, anti-oxidants, natural colorants, vegetables or spices for texture, etc.

Every time you see an instruction saying “add after trace” now you know what it means. If you remember preparation tasks, we have measured these ingredients into a small bottle. Now you simply need to pour them into the soap batter and mix with a spatula or spoon. Avoid the immersion blender as it may accelerate trace: your soap will harden very fast.

Note: Pay attention in this step to how the soap batter behaves, even if you didn’t use an immersion blender.Some essential oils may accelerate trace, making the soap to seize. These are just fancy words to explain that your soap will solidify very quickly. Soap with hard oils has increased chances of accelerating too. If you notice your soap getting thick very quickly, be swift executing the next step.

Add an Antioxidant

Some soap makers use anti-oxidants, some find it unnecessary. The role of anti-oxidants is to prevent oils that have not saponified (“superfat”) from becoming rancid over time. It does prolong the shelf life of handmade soap, in my experience.

There are 3 anti-oxidants that soapmakers use: Grapefruit Seed Extract (acronym: GSE), Rosemary Oleorresin Extract (acronym: ROE), and Vitamin E, each with pros and cons.

Personally, I advise you to always put the anti-oxidant, to avoid getting rancid soap. Note that anti-oxidants are not preservatives. This is a very common – and dangerous – misconception. Sure that these anti-oxidants, being plant extracts, have antisseptic properties, but they are too weak to work against the grow of bacteria, microbes or fungus. In soap, they are truly used just as anti-oxidants.

Soaps do not require preservatives, since, after curing, they do not contain water where bacteria can breed. But you are probably wondering “And when they are used in the shower and get wet?” They have a high pH (8-9), which greatly decreases the chances of germes to multiply. So, for both the lack of water in its composition and being alkaline (high pH), soap doesn’t need preservatives.

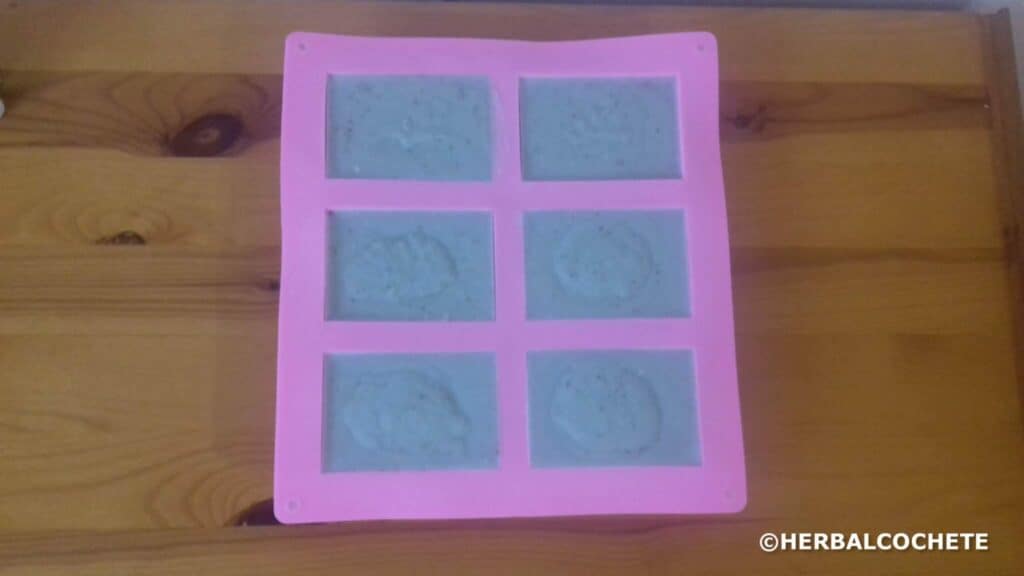

Step 8: Molding Your Soap

The soap batter is now smelling great and ready to be poured into the molds! See the post Where To Buy Soap Making Equipment for information on which molds to buy. I recommend using individual silicone molds in the first attempts, like the one in the picture (and why not foverer?). I use the one with rectangular molds a lot, gives 6 beautiful and simple bars of soap with a recipe of 450g of oils.

With these molds, you will pop out the soap bars from the mold very easily, and you don’t have to deal with the fuss of cutting soap.

With some experience, you can jump into soap bulk bars, and large soap molds, where you can make designs, like swirls and layers. In this case, you should insulate your soap mold by covering it with a blanket or towel at least till it cools down completely.

This is because gel phase will definitely happen at the center of your soap, and this way you force it evenly in all the soap bulk bar. Check out about gel phase before in this post.

If the recipe contains sugars, it will not be necessary to isolate and the soap will definitely go through the “gel” phase even without insulation. The temperature of the soap will increase more than with other recipes, even after being poured into the mold.

Molding Soap

Pour the soap batter still liquid into the mold(s). Then, tap and / or turn the mold (s) carefully so that the soap settles and releases any air bubbles.

Sprinkle with a spray bottle your soap on the whole surface with rubbing alcohol or witch hazel, to prevent soda ash – this was a hard-learned lesson (check out about soda ash before in ths post).

Attention: the soap at this point is still lye heavy and may irritate your skin or even burn! Use the safety equipment even at this stage!

Step 9: Clean up your equipment

When your soap batter is finally setting on the molds, it’s time to clean up all equipment and the working areas. Still some precautions are needed even to clean up. If you kept your work organised, and worked cleanly, you will have less work to do now.

Check this article with tips and a full explanation on how to clean up your cold process soap making equipment: How to Clean Soap Making Equipment. Some great tips to have in mind

- Do the first cleaning while the soap is still fresh and pasty, with paper towels, then throw them in the garbage

- Don’t allow big portions of liquid/pasty soap to go inside your draining pipes, as it will solidify and clog them

- Clean the immersion blender easily by diving it in soapy hot water and pulse it several times

Step 10: Unmold and Cut the Soap

You must leave the soap in the mold to solidify completely. Depending on the recipe this might take between a few hours to 2-4 days. The recommendation is to wait for 48 hours before unmolding. Not only will the soap have completely solidified, the saponification will be complete and the soap is safe for the skin (no lye). If you unmold too soon, the soap may fall apart and will only have a mess as a result …

For soaps made only with olive oil, I strongly recommend using sodium lactate or fine salt to speed up hardening. Otherwise, be ready to wait 4 to 7 days before unmolding, depending on the solidification. If the soap does not solidify within 14 days, then you must have some kind of problem. Read this article to learn more about it.

If you used the individual silicone molds, simply unmold the soaps for curing, by popping them out from the mold.

With a large soap mold (large box molds), remove the soap bulk bar from the wooden box, then pop out the silicone lining by pressing the bottom down, while pushing the sides up.

With soap bars, you don’t have to use more than a sharp knife to cut your soap into small bars. However, I prefer a wooden box with cutters, like the one in the picture.

There are more cutters, including professional ones, that can cut several soap bars at once, but they are too expensive and not worth it if you simply want to make soap for yourself and friends. Still, check out for soap cutters in Where To Buy Soap Making Equipment.

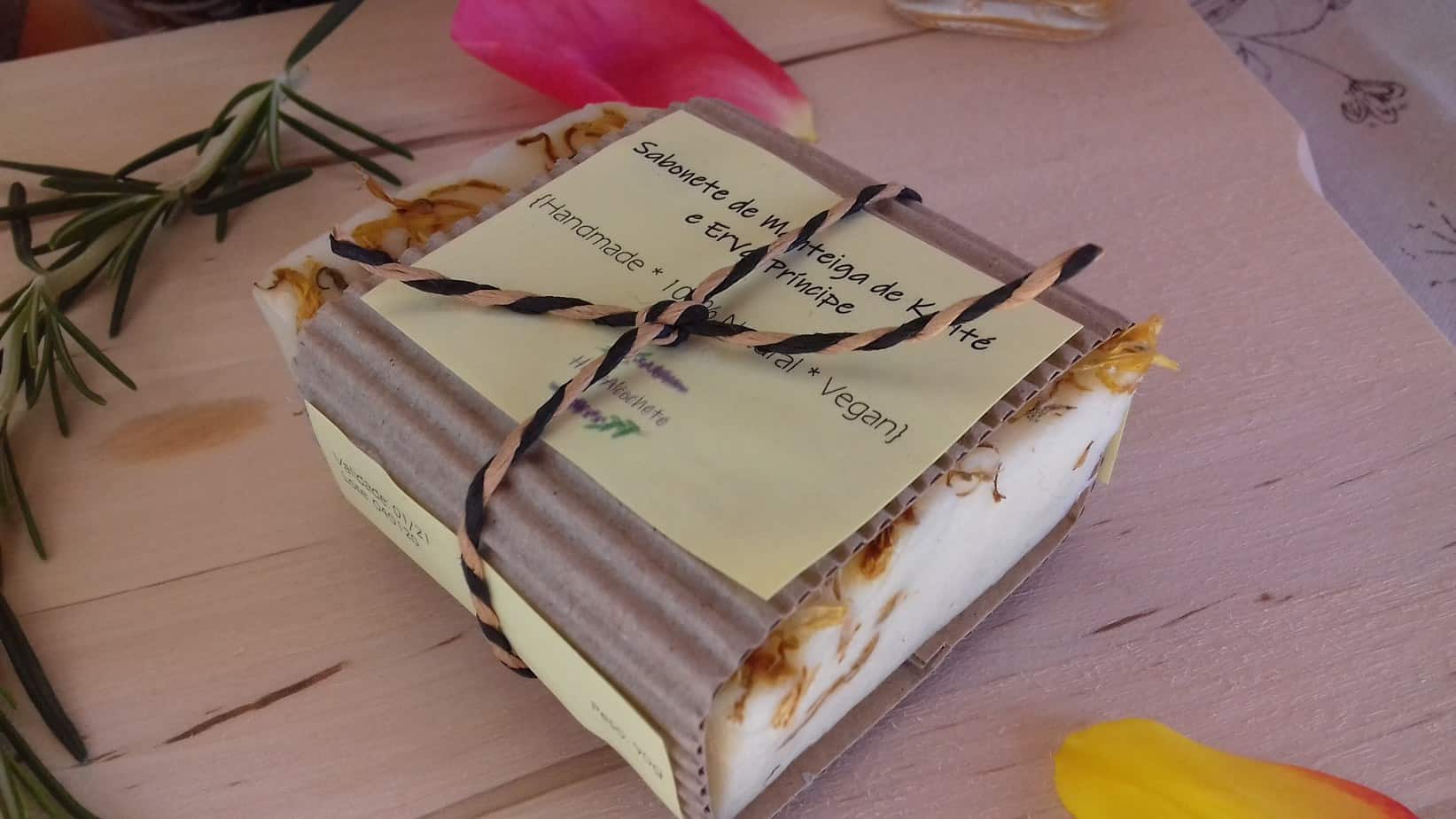

Step 11: Curing and Storing Soap

After unmolding and cutting the soaps, they can appear ready to use, having a very intense and pleasant aroma. However, they are not yet ready for use, as they need to cure, that is, they need to completely release the water that still exists in its composition and finish the saponification process.

To cure soaps, you need a well-ventilated, cool area, without too much moisture, direct sunlight or extreme temperatures. Place them on a sheet of wax paper and leave a space between them so that the air can circulate freely. Leave to cure for at least 4 weeks up to 8 weeks. See the recipes.

Mark the start and end date of curing the soaps and be patient. When you realize it, the weeks have passed and you will have your soap ready for use!

Check out How to Cure Soap and How To Store Soap.

Related Posts

Here you can find a list of other posts related with cold process soap making. You can check them out as references while you go through the tutorial.

I hope this soap making tutorial has taken away your doubts or fears of making soap at home! If you have any questions, please use the comments section.

This is a great website with the core information in two languages. Very impressive. The website is for something that I would never have thought of, making your own soap.

I liked the way you took me through the different steps of making soap and a big advantage was that I could also go through the video to see what to do.

The subject is quite fascinating when you realize that it´s possible to do this. Great subject matter.

Although it´s a long read, it´s a very specific subject and I think anyone interested in making soap would benefit greatly from reading this and watching the video if required. I might even give it a try myself.

All the best. Stephen.

Thanks a lot Stephen!

Hope you do give it a try, because it’s worth it! It’s like baking cakes at home 😀 You know what you put in it, it’s fresh, chemicals free, and will make you happier!

If you want to give a try, please, check the Recipes category for recipes, they complement this article by specifying ingredients and some of the steps.

Cheers, Sofia

these is a very good product that helps in home work with no vital effect,and these product is very soft and cool to be used.

my suggestion is that the manager of these product should try and advertise the product with a general language so that it will go round the word.

my opinion is that the maker of these product is humbly talented with these because the person has made a different and cool product.

Thanks for your comment, loveremma!

I am working in building the website in English as well so that it really goes around the world and reaches everyone 🙂

Cheers, Sofia

hellooo dear, wow what wonderfull content you have here, thanks for sharing these information , i must say you really have highlighted all the important things we need to know here, looking forward to see more of your works, thanks alot for the info, i actually read it to the end because your choice of words and writing skills is really something to save and come back for future referencing, i really do fancy these post alot, it really has made my day fun, thanks alot for the info, it has been the best so far..

Skuchmane, thanks a lot for your kind comment and I am glad my post lighten up your day 🙂

Cheers, Sofia

hello dear, thanks for presenting such a great remarkable article with us all I came across your article while doing some research online i think you have a very thorough article here finding a very good article does not come so easy so I must commend your efforts in growing such a stunning internet site I have already save this website for recommendation and future reference thanks

Thanks a lot mondayjosep, sincerely and truly appreciated your comment, it makes me want to continue 🙂

By the way, give it a try at handmade soap, it’s fun!

Cheers, Sofia

Hello there thanks for this insightful review it was really helpful I must say. Well making soap is a practical and creative DIY project. One major and important step in achieving this is by first having the right ingredients in appropriate amounts. I have made a lot of local soaps and I can tell you that it feels really great. I think this is one stuff everybody should try out one day.

Thanks a lot for your comment, Philebur!

I can relate with your feeling about making soaps 🙂 Yes, everyone should try, and the final product is really good!

Olá, quero muito agradecer a você por compartilhar esta peça perspicaz e educativa sobre como fazer sabonetes … Devo confessar que realmente aprendi muito aqui. Essas etapas são bem legais. Devo dizer que todos esses passos realmente tornam o Soap muito mais fácil e viável, Bom lá. Definitivamente vou visitar este site em outra ocasião .. Boa sorte.

Cumprimentos!

Muito obrigada pelo comentário, Thousand!

Volte quando quiser, os sabonetes são apenas o começo 🙂

Hello there, this article is a gem. I knew absolutely nothing before I saw this article. It really explained the details, the why, the how and in a way that someone who has never done it before can understand. The videos and pics were also very helpful. Absolutely love this article!

I will certainly do some recommendations.

Thanks for your comment, hillarydandy!

I am glad the article is comprehesive, the idea is really to enable just anyone to make soap at home. We all believe soapmaking to be a very chemical and complex manufacturing process, but it’s very simple, something that our grandparents used to do at home!