Once you’ve learned the basics and you know by experience what saponification or trace is, you can start a more advanced stage, in which you learn the role of each oil, and how to change soap recipes – and in the end how to make your own soap recipes!

Want to learn how to formulate and calculate your own soap recipes? Best way is to try to change one or two ingredients in a soap recipe you already know, and watch the results. Then, you can formulate your own soap recipe, by previleging the usage of your local oils.

In this article, find out how to use a soap calculator – SoapCalc -, how to add or remove an oil, change the color, use a different aroma, change the amount of water. Whether you want to modify a specific soap recipe, or make your own soap recipe, this post will guide you through the process.

A great way to complement this post is to subscribe the newsletter (at the bottom of the website) and get a free e-book about the science behind soapmaking.

If you have bumped in this post without knowing anything about soap making, better start by: How Do You Make Soap For Beginners?

Table of Contents

Notes and Preparation

From my personal experience, the production of soaps lives a lot from writing down and preparing.

Writing down the recipe and its results is very important to learn to control how the ingredients interact. Even when using the same amounts and ingredients, because we simply changed supplier of a particular ingredient, for example, or because its quality changed from one production batch to another, it is easy not to be able to reproduce the same color shade or aroma in homemade soaps. But that’s natural products for you 🙂

However, annotations help not to forget most of the variables. Writing down also helps NOT to repeat certain (bad) experiences again. Taking notes becomes even more important when we want to personalize a soap recipe, so that we know what changed – and how it impacted in the final soap.

Personally, I register temperatures, ingredients and quantities used, and special notes for every single batch of soap I make. It’s very easy to forget that apparently unimportant key ingredient or step that made the difference for your soap batch.

Another important part (probably disregarded by many) is careful preparation. Weighing of ingredients, disposition and availability of all utensils, the layout of the work areas, everything being prepared is very important for homemade soap production to run smoothly.

The preparation also involves planning the recipe itself and purchasing the ingredients in advance. Especially if we want to do something new. The following chapters of this article will describe how to formulate and calculate your own soap recipes to your liking.

Again, always write down the recipes and the respective results, and plan the recipe in advance before deciding to execute it.

Reasons for Making Your Own Soap Recipes

Finding soap recipes on the net is as easy as typing “soap recipe” on Google. So, why you might want to change a given recipe or do your own soap recipes?

Sometimes, a soap recipe can be difficult to execute because there are many differences from region to region. For example, in Portugal it is difficult to find palm oil, in other regions of the planet it may be difficult to find olive oil – or it is very expensive. Previleging local oils is something I strongly advise, as they are usually of better quality.

One very important aspect of soap recipes it’s if it is economical or not for you. I’ve found out some recipes become economicallly prohibitive with olive oil or coconut oil costing 20$/litre. Especially, when you can use pretty much any fat to make good homemade soap – you don’t need to go bankrupt!!

This is why I add a batch cost to all my recipes. And by doing so, I’ve found out that cost may vary a lot from country to country. And you do want your homemade soap to be cheap as well as high-quality. Use mostly local vegetable oils, or any fat that is a by-product for you – like lard – to make your own soap economical and sustainable to make at home.

You may also want to make your own soap because you, or someone in your family, are allergic or sensitive to certain ingredients from industrial soaps/bath gels. And, obviously, you wish to avoid them.

So, why you may want to do your own soap recipe? Find out some reasons in the following list:

- Skin allergy or sensitivity

- Cost and purchasing power

- Local ingredient availability

- Prefer vegetarian or vegan ingredients

- Prefer all-natural ingredients

- Prefer a costumized soap where you control all ingredients

- Avoid using palm oil (due to controversies in its cultivation and associated deforestation)

- You have made other soap recipes with sucess, and now you are dying to try your own ideas!!! 😀

Attention: Soap Recipes Are Chemical Formulas

For those who want to start making soap, a very important note: soap making is chemistry. We call them “recipes” for simplicity, but in reality, soap recipes are not true “recipes”, but chemical formulas, even if we are talking about homemade soap.

Modifying a soap recipe is not the same as giving a “touch” to a cake recipe. Hence the emphasis on using the right amounts with the right ingredients. Be very careful with the oils, lye and water used, as they are the base for your soap, and are specifically calculated to make safe handmade soap.

Experienced soap makers can create, change or customize soap recipes because they know and understand the oils and which combinations create a good bar of soap.

If you are starting out, I strongy advise to try the basic soap recipes, simple one-oil soaps such as olive oil soap recipe, or coconut oil soap recipe. I am careful to use a small number of ingredients in them. Just choose the most economical for you.

Oils: It Is Not Just Changing One Oil For Another

Oil + Lye = Soap

Oils and lye (100% sodium hydroxide), when mixed, undergo a chemical process called saponification. It is through this process that lye and oils bond and form soap.

At the end, you no longer have lye and oils, but the resulting soap salts: olive oil turns into Sodium Olivate, coconut oil becomes Sodium Cocoate, sunflower oil becomes Sodium Sunflowerate, and so on. These are English terms that follow the INCI standard.

This is also how you know if you are at the presence of a homemade soap or a synthetic soap (got curious? Check out Commercial Soap Ingredients – What Are They?).

Each oil is chosen for a specific purpose, and the amount of caustic soda (NaOH or KOH) is calculated to be the necessary amount to saponify each one of them.

“Superfat” is added, which means that there is a percentage of oils that will not be saponified, being used in soaps as moisturizing and conditioning agents. Also, this is how you know you WILL NOT have any lye in your soap: superfat is a sort of protection mechanism to make your soap mild, hydrating and non-irritant, with NO LYE in its content.

On the other hand, if you add too much superfat, your soap becomes too soft when in contact with water, easily melting in a messy goo you don’t have the courage to wash with. Or worse, gets rancid!

When we change one oil, whether it’s the amount or type, we are compromising the previous calculation of lye and superfat to make your spectacular soap. That is why it is not possible to simply add a “pinch” here, remove “a little” there or even change this oil for that one.

Because lye and superfat are precisely calculated for the oils in the recipe and their quantities and not for other. By modifying the oil mix without adjusting the amount of water and lye, you can end up with a batch of rotten soaps. Or worse, one that causes irritation or even minor skin burns !!!

Learn First With Tried And Tested Recipes, Invent Later!

The basic soap recipes presented on this site are simple, use relatively few ingredients, and are usually in small quantities, exactly to guide beginners in the soap making process without major disasters ?

Many of the ingredients are found in supermarkets and there are specialty soap making stores, such as Plena Natura, of Portuguese origin, which sells ingredients for soaps, among others, at affordable prices. You can also find most everything at Amazon.com.

I sincerely recommend you to try the basic recipes already tested and follow from beginning to end the tutorials How To Make Soap From Scratch and How To Make Soap by Cold Process Step-by-Step, before starting to venture into new recipes.

I must confess that I also wanted to try personalized recipes for myself at first, and “invented” my first recipe. The soap, although it was not a complete ruin, turned into “chalk” over time, as it had too much lye. Exactly because I replaced one oil with another without recalculating anything.

From there, I followed this website, the Lovely Greens, which I loved for embracing everything that is natural, but without fundamentalisms, in a practical, reasonable and unassumed tone. You can and should use it as a reference too, if you’re comfortable with English. It is my reference and inspiration for HerbAlcochete.

I never had problems with soap again !! They might not have the expected color or aroma, but they were always very good, so I never used products purchased for the bath again.

Using Soap Calculators: SoapCalc

From this point on, it is assumed that you have some basic knowledge about soap making. If you just landed here, I suggest starting at How Do You Make Soap For Beginners?

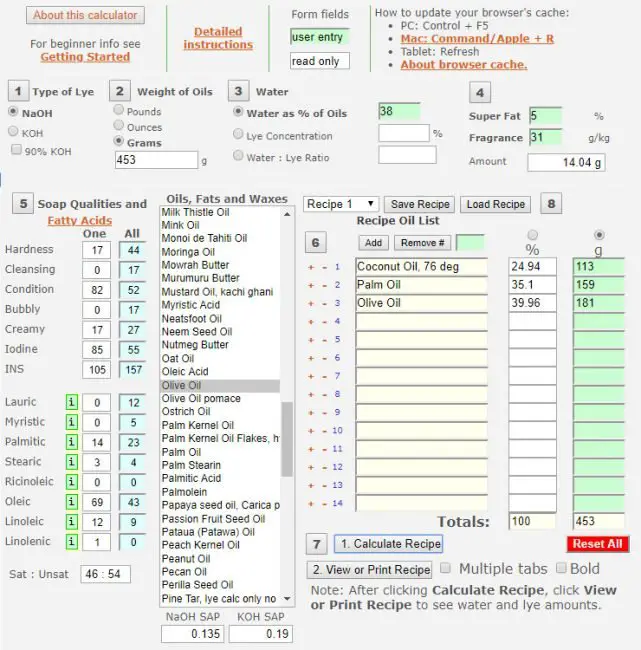

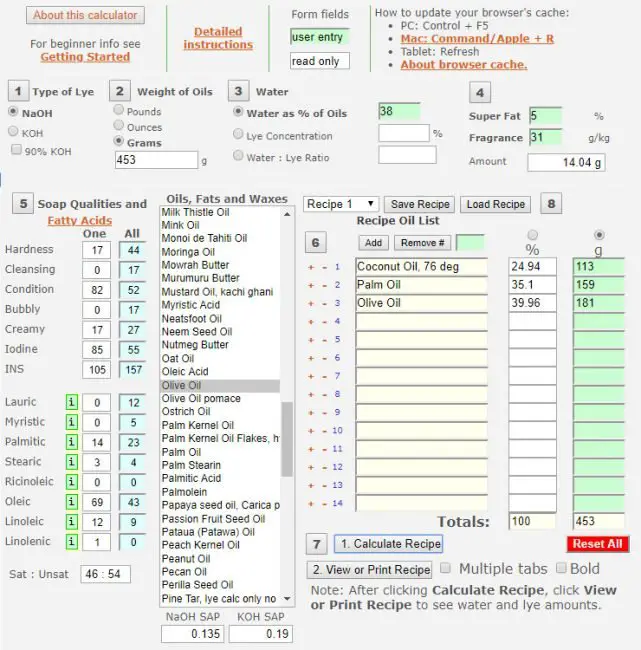

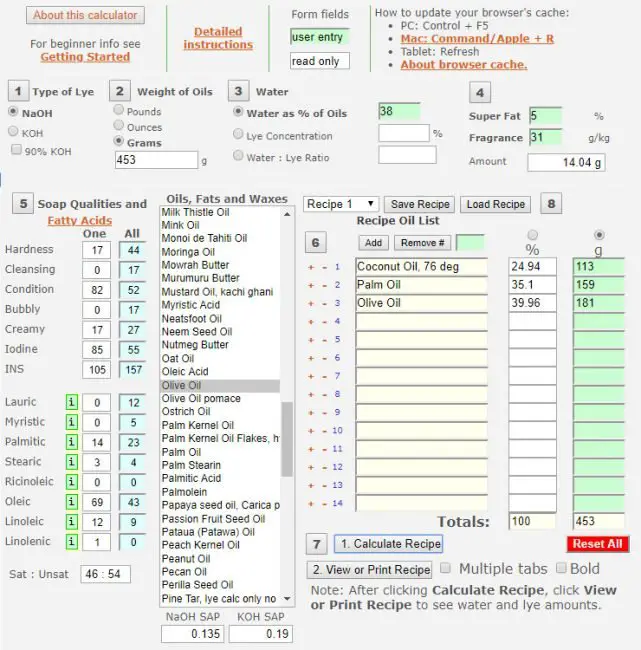

Whenever you need to create or modify a soap recipe, the first step is to use a soap calculator like SoapCalc. I have used SoapCalc since ever, and, as I got used to the layout, don’t feel the need to change. However, you are free to use your favorite soap calculator. If you don’t have one, this post tells you how to use SoapCalc.

The idea is to recreate the original recipe in SoapCalc and edit it from there.

You should start by selecting options 1 and 2 which are, correspondingly, the type of soda (NaOH) and the units of measurement (grams). Make sure that the soda and measuring units match those in the recipe.

Skip options 3 to 5 and add the ingredients in option 6. the list of ingredients is on the side.

Here are some translations:

- Olive oil: azeite

- Coconut oil: óleo de coco

- Sunflower oil: óleo de girassol

- Castor oil: óleo de rícino

- Sweet almond oil: óleo de amêndoas doces

- Palm oil: óleo de palma

- Lard: banha

- Shea butter: manteiga de karité

Make sure, after adding the ingredients, that the weight option is chosen and not the %. Record for each ingredient the weight indicated in the recipe (in grams). Then, press the button in option 7 “1. Calculate Recipe”, followed by button “2. View or Print Recipe ”. A new tab will open in the browser, with the quantities of oils inserted, and the amount of water and lye calculated for the recipe.

There should be discrepancies in the values of water and soda.

Customize Recipes With SoapCalc

Adjust the “Superfat”

There are quite a few recipes that indicate the percentage of “Superfat” that exists in the recipe (“Superfat” is the percentage of oils in the recipe that do not saponify. See more at How To Make Soap by Cold Process Step-byStep).

In this case, enter the amount of fat in option 4 “Superfat”.

However, many recipes do not have this value explicitly indicated so the amount of lye in SoapCalc, compared to the recipe, may be different.

The “Superfat” of handmade soaps is typically between 3% – 8% (with the exception of coconut oil soap). Laundry soap has a “Superfat” of 0%. Some bars of soap for washing hair contain “Superfat” of 15%.

Modify the value in option 4 “Superfat”, starting at 5% and clicking on the buttons in option 7, until you obtain a recipe with the same amount of caustic soda as the original recipe.

Do not worry about the water values and option 3 – everything will be explained in the following section “Amount of water in the recipe”.

Modify Oils

Once you have all the original recipe values entered in SoapCalc, it’s time to start customizing the recipe. You can first check out Oil Properties for Soap Making to have an idea of how much you can use and what are the properties for each oil.

Take note of the values related to Soap Qualities in option 5 (Soap Qualities): hardness (Hardness), cleanliness (Cleansing), hydration (Condition), foam (Bubbly), creaminess (Creamy). Also note the total weight of oils (option 2), water values (option 3) and “Superfat” (option 4). The changes you make to the recipe should keep all of these values close to those of the original recipe.

Now remove / add the ingredients to be modified, making sure that the total weight of oils (option 2) always remains the same.

It may take some time to adjust the quantities and types of the various oils until you get a similar recipe. Most of the time, you will need a combination of oils to replace one. An exception is palm oil and animal fat (lard). Both are fats that saponify very similarly and have a profile of fat acids similar.

TIP: As a rule of thumb, use a 40:60 percentage of saturated oils (solid fats) / unsaturated oils (liquid fats). It doesn’t have to be strict, but it is good practice when formulating new recipes. See the values at the end of option 5 (Sat: Unsat).

Amount Of Water In The Recipe

It is normal for most soap recipes to have smaller amounts of water than those indicated by SoapCalc – see option 3.

Water has 2 essential roles in a soap recipe.

- Dissolve the caustic soda in an aqueous solution that can be mixed homogeneously with the oils and start saponification

- Increase or decrease the speed at which the trace is reached. The less water you use, the faster you reach trace. The more you use it, the longer it will take to reach trace. Leanr more about soap acceleration here.

For example, 100% olive oil soap takes less water, as this oil delays trace a lot. If we use a high amount of water, it can take about 30 minutes to beat the dough until it reaches trace.

By default, SoapCalc gives a water content of 38% of oils (Water as % of oils: 38%).

However, sizing the amount of water by percentage of oils can be misleading. Why? For two different recipes that take 450g of oils, water amount will be the same, but the percentage of lye will be different. You will have a different lye concentration (ratio water:lye).

Let’s assume that one of these recipes requires 60g of soda and the other, 80g of soda. Measuring the amount of water by percentage of oils, both recipes require 171g of water. That is, 38% of 450g.

However, the first recipe will have a weaker lye concentration (60g soda + 171g water) and will reach trace slowly, while the second (80g soda + 171g water) has a stronger lye concentration and will arrive to trace much faster.

So? Use lye concentration instead. I have that value in all my recipes.

Create/Modify Lye Water

The best way to calculate the amount of water, will be starting with the amount of lye that the recipe uses.

When creating lye water for soaps, the standard percentage of lye is 25-28%. This value is the same as option 3 “Lye Concentration”. Basically, for a 25% aqueous soda solution we have 1 part of soda and 3 parts of water. That is, for a quantity of soda of 60g, the amount of water will be 3 times that of soda ie 180g (3 x 60g).

In soap making, it is normal to use a concept called “Water discount”. This simply means using a stronger soda concentration, above the standard, which, as already mentioned, allows you to get to the mix more quickly. Other desirable effects are that it reduces the curing time and prevents the problem of “soda ash” (the soap becomes whitish on its surface). Check out more at Soap Acceleration: Causes, How To Avoid It Or How To Fix It

For simple recipes that use only a dye based on olive oil or coconut oil, I usually use a lye concentration of 33% -36%. The count is easy: 36% = 36/100 = 0,36; the inverse of 0,36 is 1 / 0,36 = 2,77; 2.77 – 1 = 1.77.

That is, for a lye concentration of 36%, we are left with 1 part of lye and 1.77 parts of water: now just multiply the amount of lye by 1.77 to obtain the amount of water. For example, 58g of lye and 103g of water.

The strongest lye concentration you can use is 50% (1 part lye and 1 part water, that is, the amount of lye and water are equal).

It is not recommended to use a solution so strong in soaps, since the soap dough can reach trace so fast that it will solidify in the bowl. On the other hand, soda can have difficulties in dissolving in water, especially if the ambient temperature is above 25ºC. This can result in solid pieces of lye stuck inside the soap waiting to cause skin burns …

Soap Making Oils

In option 5 of the SoapCalc a list of terms that look like chemical expressions are listed. This option shows the fatty acid profile of the soap recipe. Each of these expressions, lauric acid, myristic acid, etc. represents the individual amount of each of these fatty acids in the oils used in the recipe.

Fatty acids are the constituents of an oil and each provides unique properties to the soap. These properties can be silky foam, stable foam, more or less soap bubbles, hydration, hardness and durability of the soap, among others.

The following table shows, for each fatty acid, the type of properties it supplies to the soap, as well as the oils where it is present in greater quantities. Oils are listed from a higher percentage of that fatty acid to a lower percentage. The oils that are most easily found in Portugal are highlighted:

| Fatty Acid | Properties it provides to soap | Oils where it is present |

|---|---|---|

| Lauric Acid | Hardness | palm seed oil, coconut oil, babassu oil |

| Miristic Acid | Hardness, Cleanliness, Soft Foam | coconut oil, palm seed oil, Babassu oil |

| Palmitic Acid | Hardness, Creamy Texture, Stable Foam | stearic acid / stearin, palm oil (RSPO), soy wax, cocoa butter, animal fat (lard) |

| Stearic acid | Hardness, Creamy Texture, Stable Foam | stearic acid / stearin, butter of Shorea Robusta (Salt), butter of Shorea Stenoptera (Illipe), shea butter, mango butter, cocoa butter |

| Oleic acid | Hydration, Sliding Texture | sunflower oil, japanese camellia Oil, olive oil, hazelnut oil, shea oil, sweet almond oil, apricot kernel oil, peach kernel oil, canola oil, avocado oil, peanut oil, shea butter |

| Linoleic acid | Hydration, Silky Texture | evening primrose oil, grapeseed oil, poppy seed oil, passion fruit oil, hemp oil, cotton oil, corn oil, rapeseed oil, hemp seed oil, soy oil |

| Linolenic Acid | Hydration, Softness | hemp oil, linseed oil, and in lower percentages in olive oil and sunflower oil |

| Ricinoleic Acid | Hydration, Stable Foam | castor oil |

When creating or customizing a soap recipe, so that we don’t get caught up in the middle of so much variable, it is important to pay attention to Soap Qualities in option 5, especially the value of the INS parameter: you must always try to approximate the recipe to the recommended value ranges.

Many soapmakers may claim that they have created great recipes with some values outside these recommended ranges. However, they become a good standard to follow and I have not yet experienced a bad recipe every time I follow these guidelines.

The following list shows the most common oils used in soap making and the recommended percentages in recipes:

- olive oil – up to 100%

- coconut oil – 15% to 30% (with the exception of 100% coconut oil soap)

- palm oil (RSPO) – up to 50%

- sunflower oil – 5% to 20%

- sweet almond oil – 5% to 20%

- castor oil – 3% to 10%

- shea butter – 5% to 15%

Customize The Soap Fragrance

When we want to personalize a soap recipe, we often just want to use a different scent. When it comes to using essential oils or fragrances, it is necessary to be equally rigorous in using the right amount. If it is too little, the soap scent may be too weak. If used too much it can cause complications such as skin irritations or allergies.

There is a difference between essential oils and fragrances. Fragrances are not completely natural, they are basically patented perfumes. Some fragrances can only be used on candles, others are safe for the skin. They usually come with recommendations on how much to use in “leave-in” products (lotions, creams, etc.) and in wash-off products (soaps, shampoos, etc.). Always follow these recommendations. If the quantities to be used are not clear for a particular fragrance, contact the manufacturer.

SoapCalc has its own field to be able to know what the maximum fragrance value can be used in the manufacture of soap, see the “fragrance” field in option 4, be it essential oils or fragrances. The value is in g / kg soap, that is, 31g / kg fragrance corresponds to 15,5g for 500g of soap and 31g for 1 kg of soap. However, this indication should never override the manufacturer’s recommendations.

Modify A Fragrance

It can be confusing to understand how to apply fragrance recommendations.

Basically, in the particular case of soaps, if the maximum percentage of use for a fragrance is 3%, it will be 3% of the total weight of oils, caustic soda and the fragrance itself. The water does not count for the total weight of the soap, as it will disappear completely during curing.

Therefore, for 450g of soap, the amount of fragrance is 13,5g (450g x 0,03 = 13,5g).

Modify Essential Oils

Essential oils are distinguished from fragrances because they are more natural. Essencial oils are volatile aromatic compounds extracted from aromatic plants by distillation or fruit compression processes. They are not formulated in the laboratory, they are limited to a high concentration of essential oils from the plants themselves.

Thus, while fragrances work well using only one, as they are a specifically formulated perfume, essential oils are different: they work best in mixtures, although there are some that can be used alone.

Mixtures of essential oils consist of one or more oils, but mixtures that work best are those that contain at least one base note essential oil, one middle note essential oil, and one top note essential oil (which is smelled first). See also Essential Oils to Make Soap.

For beginners, the advice is to start by using one or two essential oils to taste and start with mixtures with more experience. Very common essential oils are: lavender, eucalyptus, rosemary, sweet orange, peppermint, lemongrass and rose (rose absolute, normally diluted) .

Regarding the quantity to be used, the maximum value of 31g / kg is a good reference, however, soon one realizes that essential oils are expensive and 31g weighs a little in the wallet, especially for an optional ingredient. Although it is not a correct approximation, because the densities of the different essential oils are different, I usually approach the SoapCalc value of 31g in ml, and use 31 ml of essential oils in 1Kg recipes, or 13ml in 450g recipes which are common on this website.

Customizing Soap Color

There may be a soap recipe that you are interested in trying, but you want to change the color, or the type of dye. In this case, the change is simpler, as it is enough to replace the original dye with another one. You can also not use any type of dye and leave the soap with its natural color, derived from the oils used.

There are numerous ingredients that can be used as dyes for soaps. Some are natural, others are not. Some are reliable and easy to use, others are a little more unpredictable. I confess that, despite never having bad results, the issue of dye is the one that gets out of my control. It is very common to try to obtain a certain color and turn out the color on the side: instead of orange, I obtained yellow or mustard color.

Attention to the color that is obtained when the soap is removed from the molds, 24 to 48 hours after manufacture, it usually differs slightly from the final color. There is no point in throwing out any soap production because we wanted lilac and it came out grayish brown. The color of the soap changes with healing. Always wait 4 to 6 weeks to see the result. In addition, you can always use the soap even with an ugly color ?

In the recipes I make, I always try to use kitchen ingredients and plants to add color to the soaps, however, until now I have only succeeded in controlling the tones by using the most common natural mineral dyes: oversea, iron and chromium oxides, micas and even cosmetic clays.

See more in How To Color Soap With Kitchen Ingredients

Create Your Own Soap Recipes

Now that you have learned how to change oils, lye and water amount, fragrances and colors in the previous chapters, you are ready to start your own soap recipe ideas!!! Just follow these steps:

- Think about your own ideas

- Use local ingredients when possible

- Write down the recipe

- Use a soap calculator

- Check the soap theoretical values: do you have a balanced soap?

- Take notes of the resulting soap

Be aware some recipes will not go right, whether the reason is ingredients choice, amount or quality, or the process itself (too low or too high temperatures, mixing the batter for too long). Be ready to make mistakes and learn with them.

Check out my post about Soap Acceleration: Causes, How To Avoid It Or How To Fix It, to sort out some common issues with soap making.

Hope you found this article helpful! If you still have any questions or wish to make a suggestion, please, leave a comment below.

Related Posts

- Where to begin with Soapmaking: How Do You Make Soap For Beginners?

- Soap Making Methods: How To Make Soap At Home

- Cold Process Tutorial: Learn To Make Cold Process Soap

- Hot Process Tutorial: How To Make Hot Process Soap

- Liquid Soap Tutorial: How To Make Liquid Soap With Potassium Hydroxide

- Soap Acceleration: Soap Acceleration: Causes, How To Avoid It Or How To Fix It

Great article, very detailed and with the SoapCalc information it is quite a tutorial.

My oldest son has made soap using our goat milk (yes, we live on a farm) and sold it to very appreciative customers. The process is not as simple as baking cookies, as you explain very well. But he developed his craft using the precision necessary. It helps that he is a very precise person when it comes to recipes.

His experience gave all of our children a lesson in chemistry, too. While his true farm business now takes up more time and does not allow for soap making right now, I do hope he or one of his siblings finds time to do so again. Our customers and our family benefited from the customized soap blends. He made them using only natural ingredients as I am intolerant of artificial fragrances.

Thank you for sharing such great information. I might have to encourage a family soap-making day!

Hello Diane, this is what my blog is all about: wanting to share these experiences about soap making 😀

Goat milk soap made with goat milk coming from your farm, to me, sounds better than many luxurious cosmetics! And a family soap-making day looks so good especially in this pandemic time where these small pleasures take a whole new importance, you should do it.

I make soap-making days in many weekends 🙂 Goat milk is not common in my area, but I plan to try at least once to do it in one of those weekends, especially if I get goat milk from a farm as well.

If you like, share your recipe here!

Thanks for your very nice comment.

Cheers, Sofia

Very interesting article. there a so much to learn with a lot of details. Never thought that there was a great tool to use to make soap. Now i have to be very careful with all the home made soap as some may not be balance and i can ask more question before buying.

To understand this phrase means that those how say its all natural no chemical are not being honest ? ”To make it clearer, soap recipes are not true “recipes”, but chemical formulas, even if we are talking about the manufacture of natural soaps.”

With the options i would could not follow easily on how to use the calculator as the picture seems the same.

Do we add the amount of water to the calculator?

Hello Eve, thanks for your comments!

So, I understand that using SoapCalc is a bit dificult? I might do a video about it, will be easier to see how it works. No you don’t add the amount of water, just how strong you want your lye water (usually around 30% lye, 70% water). Water and lye quantity is what SoapCalc calculates 🙂

Please, understand that SoapCalc tool is mostly used by people with experience in soap making, this post only teaches how to change a recipe, for example, if you need to change a quantity of a certain oil, or replace one oil for another. Anyway, there are more things to consider than just change quantities (as explained on the post).

If you wish to start making soap at home, I strongly suggest to try recipes without changing them first, at least 3 or 4 different ones, and then read about what each ingredient does in soap. Then, you can (and should) use SoapCalc to change a recipe.

“To understand this phrase means that those how say its all natural no chemical are not being honest ?” When people advertise a “all natural soap, no chemicals”, what they are trying to inform that their product has no artificial, laboratory created chemicals. Many commercial soaps are made with other ingredients, like surfactants (SLS, etc.) or detergent substances, preservatives, perfumes, artificial colorants, to make the soap to wash well, last a long time with good aspect, look pretty, smell good… Most of these substances are very processed and very far from the natural ingredients, much more like harsh chemicals.

Natural soaps are made with oils and lye, and have almost no chemical processing before you get your soap, actually it’s just the chemical reaction that changes oils and lye into soap. Therefore, the expression “all natural, no chemicals”.

Hope this explanation answered your question.

Cheers, Sofia

hello Sofia,

I must say that I’m impressed by your informative post on how to make soap using soapcal.. it’s really fun when you take up the courage to make some of the things you spend money on buying from the grocery shops,it gives you some form of responsibility…thanks a lot for sharing this useful information I look forward to giving it to try….

have a great day and stay safe..

Thank you for your comment, evansese!

And thanks for enjoying the post. Soap making is fun!! I like to describe it as magic happening before your eyes (actually it’s just a chemical reaction, but it’s still fun).

But if you wish to give it a try to soap making better start with

https://herbalcochete.com/how-do-you-make-soap-for-beginners/

and then

https://herbalcochete.com/learn-to-make-cold-process-soap/along with a recipe of your choice from https://herbalcochete.com/category/recipes/

SoapCalc is for folks with some experience. Thank you for your comment because I probably should make it clearer.

Be well.

Cheers, Sofia