Servings: 6 soap bars

Cost: $5 - $10,20 / 4€ - 10€

Equipment

Ingredients

Lye Water

- 189 g tomato puree distilled water with 2 tbsp of tomato puree

- 69 g lye (100% sodium hydroxide)

- 10 g citric acid

- 1 tsp fine sea salt

Oils/Fat

After Trace Ingredients

- 6 drops grapefruit seed extract (GSE) (anti-oxidant) or rosemary oleorresin extract

- 13 ml essential oils blend tomato leaf fragrance oil

Essential Oil Blend

Instructions

Get Ready!

- Wear goggles and gloves! Look at “Safety Precautions” in the video above or in Soap Making Safety Precautions

- Watch the video above about "Cold Process Soap Making Tutorial" or read the post Learn To Make Cold Process Soap for instructions on cold process soap making before starting. These are generic but important steps for all recipes.

- Prepare the tomato puree in advance: check Google for recipes on how to do it, there are several ways. I have simply cooked some tomatoes, and blended them into a puree. 3 tomatoes should be enough to make around 200 ml/6.76 fl oz of tomato puree. If you don't have enough for the lye water, add water.

- Assemble everything: ingredients, equipment, safety equipment. Prepare your workstations. Measure all the ingredients. Don’t start the recipe without having everything ready!

Heat the Oils

- Heat all your oils in a pyrex bowl at the microwave until the coconut oil melts. Use 1 min periods and check temperature. The oils shouldn't overheat (> 60 °C)

Make the Lye Water

- Make the lye solution according to How To Make Lye Water, using the tomato puree instead of distilled water. Add the citric acid before the lye. Mix it well until the vapors start to dissipate.189 g tomato puree, 69 g lye (100% sodium hydroxide)

- ATTENTION: beware that you will have a volcano effect due to the sugary content of tomato puree!! Be fully equipped with your safety equipment, make sure your area is prepared for some lye water spillage - place some paper towels below your pitcher.

Make the Soap Batter

- Use as target temperature 25 °C for the oil-solution mixture, or as low as you can while keeping the coconut oil fully liquid. The lye and oils should not have a difference of more than 10ºC/ºF between them.

- Pour the lye water into the oils carefully, using a spatula or the edge of the bowl

- Mix oils and lye with the immersion blender.

- Add the oat powder in the meantime.

- Reach trace with the immersion blender. With a high olive oil content and low temperatures, this soap batter might take some time before reaching medium trace. As long as the soap is fully emulsified - no floating oils -, looking like in the picture, you don't need to reach medium trace.

Add After Trace Ingredients

- Add the extract and the essential oil blend. Mix with a spoon or spatula. In this special case, you might do it with the immersoin blender as well.6 drops grapefruit seed extract (GSE) (anti-oxidant), 13 ml essential oils blend

Molding and Curing

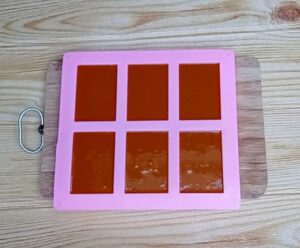

- Pour the soap in individual soap molds and sprinkle with alcohol or witch hazel.

- Let it set for 48 hours.

- Learn how to clean all equipment with How to Clean Soap Making Equipment.

Curing the Soap Bars

- Unmold the soaps after 48 hours and let the bars cure for 4 to 6 weeks in a ventilated place. See How To Cure Soap and How Do You Store Homemade Soap?

- Enjoy your soaps!!

Tried this recipe?Send a pic to @herbalcochete!